Hemmingen Site

Since its change in entity, the Hägglunds Vehicle GmbH has always been closely linked to the region of Hannover which represents a strategic choice in terms of infrastructure, both nationally and internationally.

To be able to achieve the best possible efficiency for our customers, we have moved into our new facilities in Arnum in the south of Hannover in October 2011. With a surface of approximately 1,600 sqm, we have the logistic possibility to maintain a high availability of frequent and also non-frequent spare parts and consequently reduce the lead times to a low level. Furthermore, we also have the possibilities to hold seldom spare parts in readiness and avoid obsolescences.

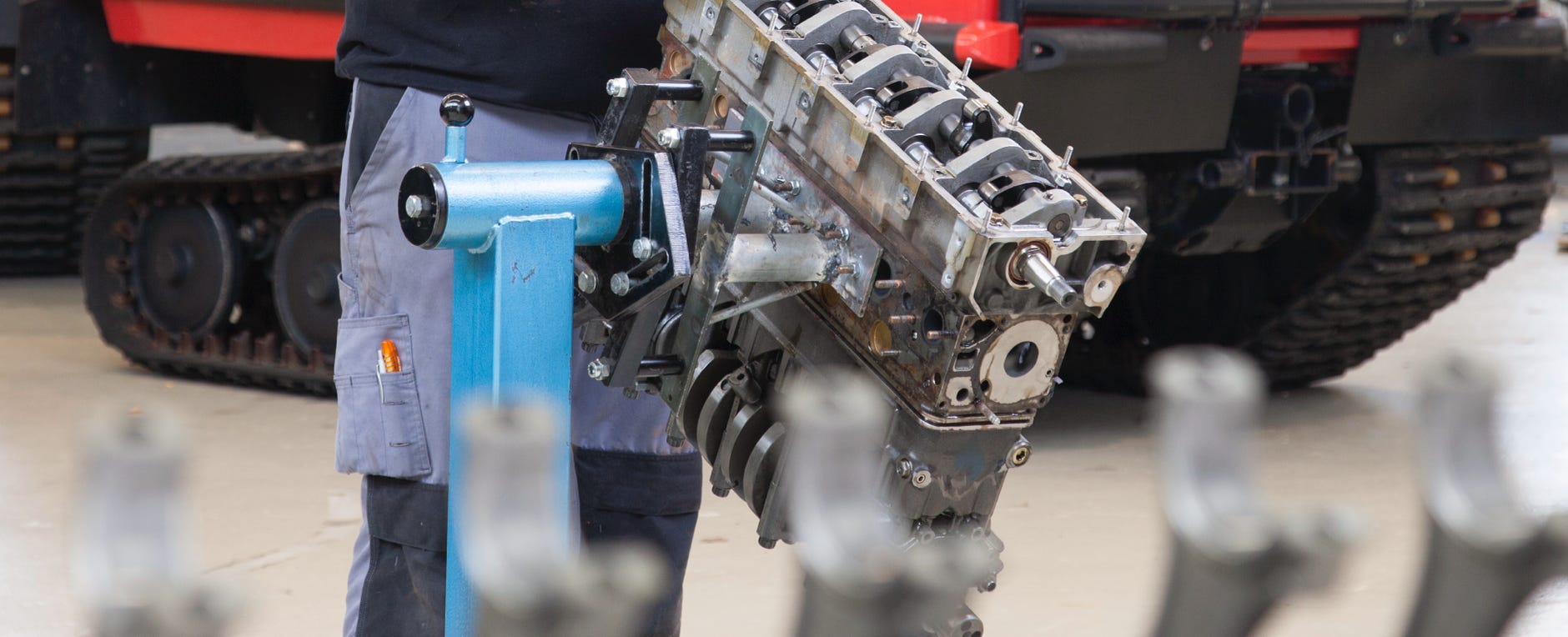

A further core area of our head quarter is the workshop area whose 200 sqm offer two adequate working places for repairs and maintenance.

Equipped with all necessary special tools we have the potential to repair complete vehicles but also single LRUs, as engine or gearbox, of those.

The customer and office area, separated from each other, stretches out over another 450 sqm on two levels. Here, the office area forms the company’s “nerve center” from where we daily are at your disposal.

Hägglunds

Since more than 40 years

At this time, the company is named Prinoth Germany Snow Vehicles GmbH. In 1985, while participating in an exercise maneuver of the Allied Command Mobile Force in Norway, the Bundeswehr quickly realizes that the well-proven mobility of the Unimog comes to an end in the rough terrain and weather phenomena of the Nordic countries. The Norwegian forces, already equipped with Hägglunds Bv206, can be seen as the pioneering task when proving the outstanding mobility of their vehicles. Subsequently, the Bundeswehr places an order with immediate necessity for 12 vehicles which are directly delivered from Sweden to the Bundeswehr in Norway. The following spare part logistics, as well as the technical and logistical support, are carried out by the Hägglunds Prinoth GmbH, its new entity, in Germany. Directed by its executive Wulf Rinke, the company establishes an unobstructed spare part supply chain and maintains the vehicle’s documentation on an up-to-date level.

In February 1989, the company’s entity is changed to today’s Hägglunds Vehicle GmbH. The head office is moved to Isernhagen nearby Hannover where, from now on, miscellaneous modifications of the in-use vehicle system are overseen. Further orders for vehicles are placed until the middle of the nineties, making the number of Bv206 D in the Bundeswehr grow to a total of 168 vehicles. With their high mobility, those are mostly in use in the battalions of the mountain infantry.

The positive echo from the German forces quickly attracts the attention of civil institutions. Amongst others, the „Technisches Hilfswerk“ and the German coast guards are convinced of the high mobility and ability of the Bv206. The Hägglunds Vehicle GmbH, as it is called from now on, therefore enlarges its duties and responsibilities and becomes the central strategic partner for the German market. Fulfilling this task the Hägglunds Vehicle GmbH services further vehicle orders from the above-mentioned institutions and accompanying service contracts.

Still, the German army remains to be the biggest customer who, in the middle of the nineties, decides to procure a new vehicle system with a higher protection level. This decision is mainly based on changed security requirements to protect soldiers as best as possible. Why not go for a known trustworthy solution? In the following years, the Bv206 S finds its way into the Bundeswehr, leading to a total of 189 vehicles throughout several purchase orders. Like for the Bv206, the German government signs contracts for spare part logistics with the Hägglunds Vehicle GmbH.

In 2009 the company has to compensate a big loss – the longtime managing director Wulf Rinke loses his fight against a short but hard illness. As an interim solution, the Swedish mother company names Lars Pihl as his successor until Mattias Strandberg becomes the new managing director in 2010. Under his direction the track record of the Hägglunds Vehicle GmbH continues proceeding. Inter alia the marketing campaign for the BvS10 in Germany is carried out for the first time in the end of 2010 under the direction of Mr. Strandberg.

Extended fields of actions as well as the expansion of the team to now seven employees require the move of the company into its new premises in Arnum in the south of Hannover. From here the team, since 2018 under the management of the Swedish managing director Anders Lundgren, operates as the central point of contact for the German speaking region as well as logistic partner of the mother company – 24 / 7, worldwide.

Airshot of new Site

But let us start at the beginning of a long and eventful company history:

It was in 1899 when Johan Hägglund founds the original mold for today’s big group, the company Hägglund & Söner in Gullänget nearby Örnsköldsvik. At that time, the core business was the carpentry, specialized in the manufacture of furniture. But soon, the company extended its business and became one of the biggest industrial companies of the Norrland region, starting in 1924 to manufacture also busses, cranes and trolley cars. From 1932 the company also built smaller airplanes. In 1970, the company made the first touch with the military market when the Swedish FMV, being the governmental purchasing agency, decided to designate a replacer for the Bandvagn Type 202 which was manufactured by Volvo. Hägglund & Söner applied for the call for tenders and started developing first prototypes of the Bv206 after having been contracted. The first batch production started in 1979 with an amount of approximately 3,500 vehicles.

In the meantime, more precisely in 1972, the company was incorporated into the Swedish industrial group ASEA – still, the company remained in Örnsköldsvik with its production line. During 1988, the ASEA-group consolidated with the Swiss Brown Boveri concern which led to far-reaching consequences for Hägglunds.

As the new formed ABB-group (Asea Brown Boveri) had put its focal point onto the electrical industry, there was no concrete appropriateness for the products and services of Hägglunds. Consequently, the Hägglunds Incentive Group was formed, a so-called “rest-ASEA group” which was divided into five sectors. The sector of Hägglunds Components, mainly active in building mining machines, was taken over by the Gia Industri AB, the sector of electric drives was integrated in the company ABB Traction.

Today, the three remaining Hägglunds-entreprises are still major employers in the region around Örnsköldsvik. The crane division has been taken over by McGregor Cranes (which is part of today’s Cargotec Corp.), the hydraulic division belongs to the Bosch Group. The vehicle division first merged into the Alvis PLC and then passed into the ownership of BAE Systems in 2004.

Within the BAE Systems PLC group, the company belongs to the “Platforms & Services” sector and manufactures middleweight infantry fighting vehicles, protected all-terrain vehicles and electro-hybrid drives at the company’s headquarters in Örnsköldsvik, Sweden. Furthermore, the company completes other vehicle systems under license for the Swedish army, amongst others the Leopard 2 developed by the German defense company KMW. The site also represents the group’s central office in terms of vehicle support services, including maintenance, training and overhaul-programs for all vehicle types.

As for today, BAE Systems Hägglunds AB has approximately 2.000 employees in Sweden. Taking all markets into account, the BAE Systems PLC group employs more than 93,000 employees in over 40 countries, making it part of the elite of international defense companies.